Installation Nstructions

Preparation Before

Installation

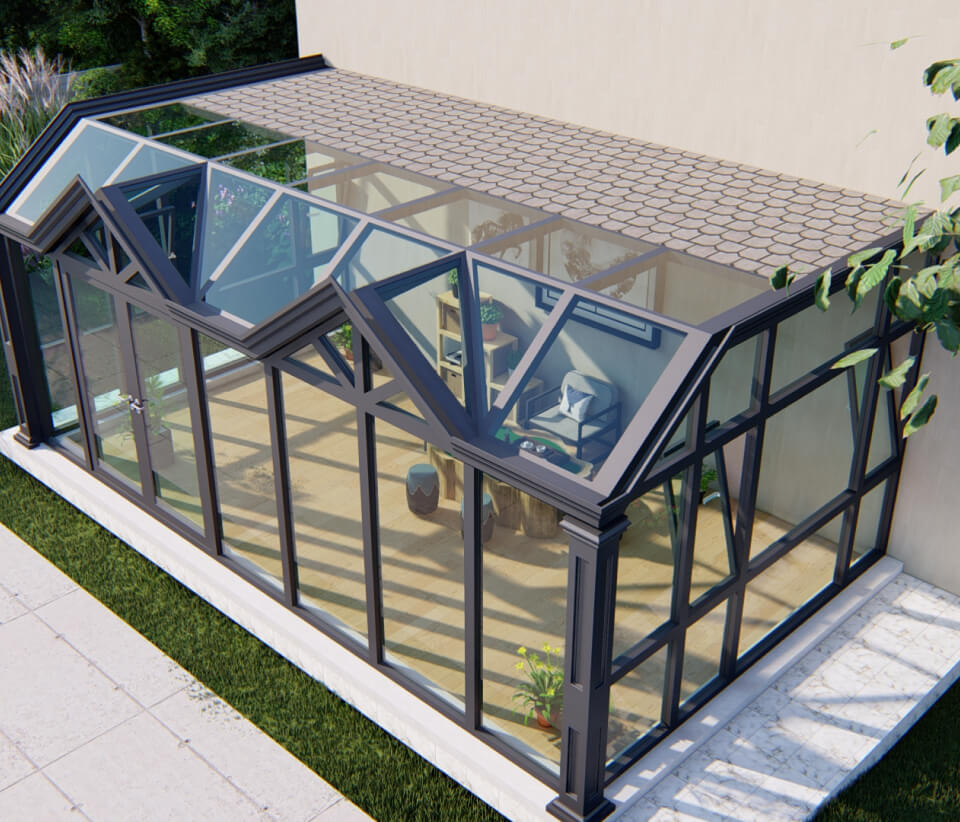

01. Confirm the construction site: Confirm the installation site location and floor height

2.Measurement: Measure the length and width of the installation location,as well as whether the diagonal dimensions are consistent.Allow measurement data deviation of ±2mm

3.Leveling: Use a spirit level to find the level of the on-site civil engineering,and use the highest point of the level as the installation level.

4.Record dimensions: Record detailed dimensions on the measuring book

5.Proofreading renderings and construction drawings: Based on on-site measurements,refine the renderings and construction drawings.

Check materials and drawings

before installation

Verify materials:Check whether the quantity, specifications, andquality of materials meet the requirements

Check the drawings:Confirm that the drawings match the actuasituation on site without any omissions or errors

All product debugging and completion

Electronic product debugging:

Debugging electronic products such as LED lights and sunroofs

Debugging of door and window glass:

Debugging door and window glass to ensure smooth sealing and

opening/closing,Installation

completed, clean up debris and garbage on site, and do a good job of final cleaning.

Franchise Process

Aisite The Factory

Intention To Negotiate

Authorization

Technical Training

Order Interconnection

Normal Operration

Aisite The Factory

Intention To Negotiate

Authorization

Technical Training

Order Interconnection

Normal Operration